Swiss Village Reborn: Home to the World\’s Tallest 3D‑Printed Tower

White Tower of Mulegns: Poised to Rise as World’s Tallest 3D‑Printed Landmark

Structural Highlights

- Height: 30 metres

- Material: Advanced 3D‑printed composite

- Design: Sleek white façade with adaptable modular floors

Opening Schedule

The grand opening is slated for June 2025, welcoming visitors to a cutting‑edge cultural hub.

Future Impact

- Transforms into a vibrant arts and community centre

- Showcases sustainable, low‑carbon construction practices

- Sets a new global benchmark for 3D‑printed architecture

Rediscovering the White Tower of Mulegns

• A Modern Day Marvel in the Swiss Alps

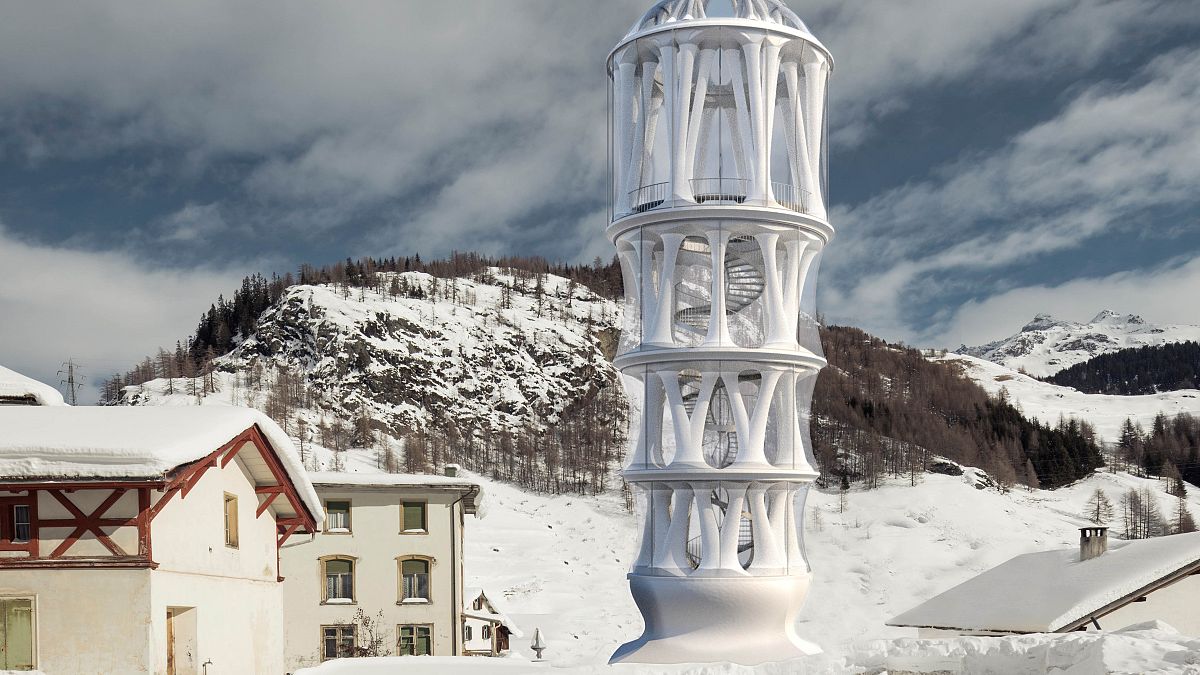

The White Tower of Mulegns towers majestically amid the icy grandeur of the Swiss Alps, presenting a sight that is as if lifted straight from a science‑fiction saga.

Clad in a pale, almost translucent ivory, the structure unfurls into the high‑altitude valley, resembling an ancient tree that has weathered centuries of snow and harsh mountain winds. Its robust framework echoes the sturdy backbone of a living tree, ready to endure deep‑cold winters and the relentless gusts that sweep through the alpine pass.

Key Attributes of the Tower

- Structural Resilience: Designed to resist the extreme temperatures and high winds that typify this mountain region.

- Visual Authenticity: Derived from the silhouette of a vintage forest stalwart, it mimics the enduring form of a long‑lived tree.

- Location Advantage: Situated directly in front of snow‑capped peaks, its presence amplifies the awe of the surrounding alpine landscape.

Why It Stands Out

Unlike conventional alpine architecture, the tower’s ice‑reminiscent façade and tree‑like structure give it an almost ethereal and timeless quality, captivating both locals and visitors alike.

Tor Alva: The Rising 3D‑Printed Tower of the Julier Pass

In the fading twilight over the Julier mountain pass, a vivid 3D projection gives rise to the Tor Alva, a striking abstract tower that promises to become the world’s tallest 3D‑printed structure by its expected completion in June.

Design and Purpose

- Height: 30 metres.

- Function: A fusion of concert hall, art installation and monument.

- Location: The village of Mulegns, tucked in the heart of the Julier Pass.

- Goal: To revive the dwindling rural community and attract visitors for cultural experiences.

Historical Context

The idea for Tor Alva emerged three years ago as part of an initiative to breathe new life into the neglected settlements of the Julier Pass—once a pivotal trade corridor linking Northern and Southern Europe.

Today, the population of Mulegns has dwindled dramatically from its 19th‑century peak, with only about 16 residents remaining. Numerous buildings stand abandoned, evoking a quiet, almost eerie atmosphere.

Vision of Cultural Renewal

Nova Fundaziun Origen, a regional cultural foundation, proposed that a landmark such as the Tor Alva could be the key to transforming the region. By creating an engaging, iconic structure, the hope is to:

- Encourage travelers to pause and explore.

- Host performances and cultural events.

- Provide accommodations, enticing visitors to stay beyond a single night.

Future Prospects

Once completed, the tower will not only be a marvel of engineering but also serve as a living testament to the resilience and creativity of the Montérégie region, offering a beacon of hope for its community and a centerpiece for cultural enjoyment.

A Digital Dawn Over the Tor Alva

Hansmeyer/Dillenburger

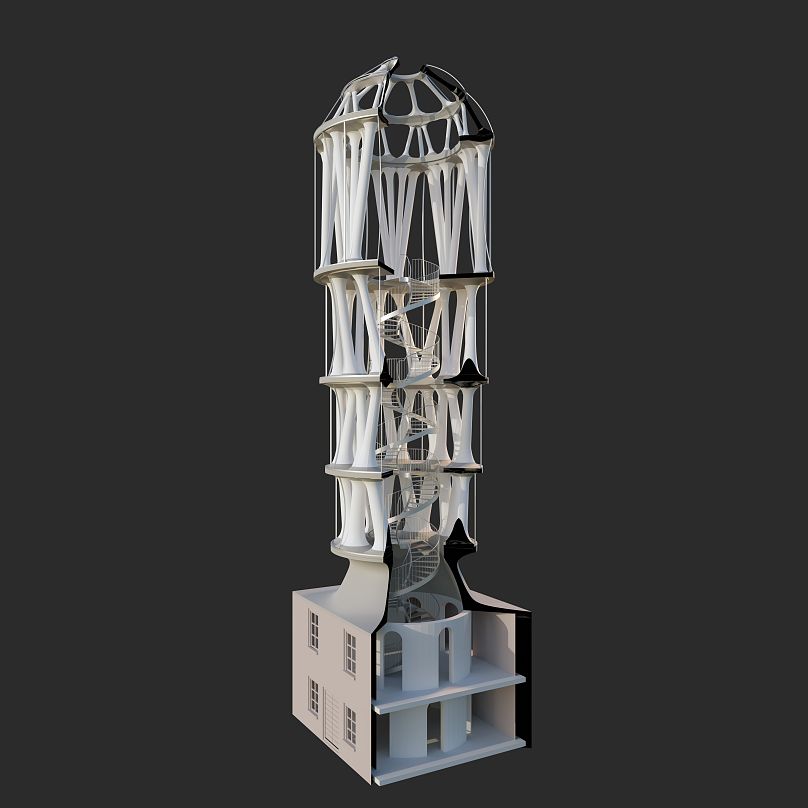

As twilight descends over the high Alps, a 3D rendering brings the historic Tor Alva to life, soaring dramatically from the heart of the Julier Pass. This immersive visualisation captures the fortress’s imposing silhouette against the darkening sky, offering viewers a virtual glimpse of its storied presence.

The projection, crafted with meticulous attention to architectural detail, showcases the tower’s robust stonework and sweeping silhouette. It positions the structure against the rugged backdrop of the Julier mountains, illustrating how the tor stands resilient amid the surrounding landscape.

During the evening break, viewers can witness the transitions of light—from the last amber rays of day to the deepening shadows—effectively narrating the tor’s enduring strength and historical significance.

An exercise in creative teamwork

Tor Alva: A Modern Construction Milestone

Standing tall in the Swiss landscape, Tor Alva exemplifies the cutting‑edge of engineering ingenuity. Over the past decade, it has seen the collaborative efforts of dozens of engineers, material scientists, and research specialists.

Key Contributors

- Engineering Design Team – orchestrated structural calculations and load assessments.

- Material Specialists – selected advanced concrete composites for durability.

- Research Coordinators – guided experimental phases and quality control.

- Technological Partners – supplied the 3D extrusion equipment.

Innovative Construction Technique

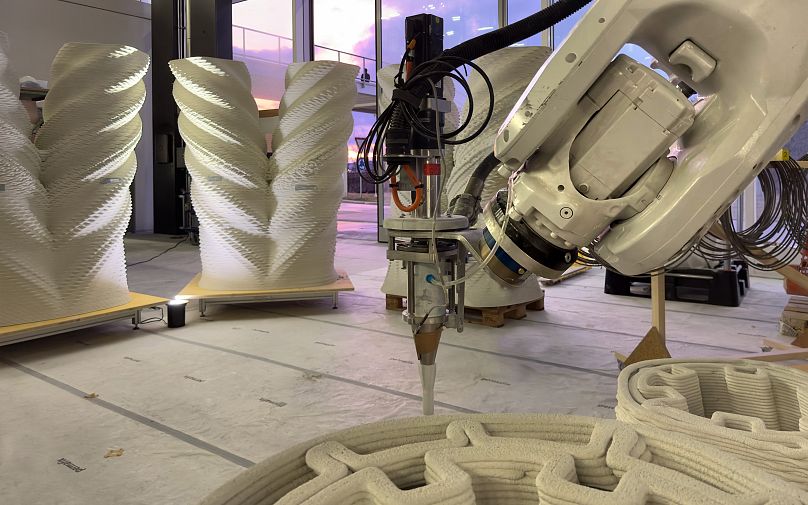

The tower’s foundation is built from a special 3D‑printed concrete mix, developed in collaboration with the Department of Building Technology at the Swiss Federal Institute of Technology (ETH) in Zurich. This extrusion process allows precise layering, creating a robust framework while minimizing material waste.

Looking Ahead

Tor Alva is not merely a static structure; it serves as a prototype for future urban architecture. Its success demonstrates how modern fabrication methods can blend aesthetic appeal with structural efficiency, paving the way for new skyscrapers worldwide.

The Revolutionary Tor Alva: Concrete Meets Steel in Once‑Unthinkable Heights

Bridging innovation and structural integrity, the Tor Alva stands tall as a paradigm of contemporary architecture. Crafted from ultra‑white concrete, its form is the product of a newly refined extrusion technique that traces back to pioneering research at ETH Zurich.

Architects Behind the Vision

- Michael Hansmeyer – renowned for pushing computational design to its limits.

- Benjamin Dillenburger – a trailblazer in digital fabrication who helped shape the building’s silhouette.

A Novel Integration: Rebar in 3‑D Concrete

Despite years of 3‑D concrete printing, the Tor Alva is the first project to embed steel reinforcement rods, or rebar, directly into the printing process. This breakthrough grants the structure the necessary robustness to ascend to unprecedented heights.

“Until recently, rebar was absent in this modality,” said Hansmeyer during a interview with Euronews Culture. “Now, by integrating steel within the extrusion, we’ve unlocked the possibility of constructing much taller buildings.”

Construction Efficiency and Design Highlights

- 32 pre‑fabricated columns, enabling rapid on‑site assembly.

- Five progressively brighter levels accessed via a winding staircase.

- Topmost level houses a domed venue, designed for performances and gatherings.

As visitors ascend, each floor becomes more luminous and airy, culminating in a spectacular, dome‑shaped space that promises an unforgettable experience.

Structure Overview

The 30‑metre‑tall edifice is assembled from 32 Y-shaped supports and is organized into five distinct levels. These tiers are traversed by a central, spiral staircase that winds through the core of the design.

- Height: 30 metres

- Columns: 32 Y‑shaped columns

- Levels: 5 tiers

- Staircase: central winding (spiral) design

New Performance Space Opens on Tower’s Top Floor

Visitor Capacity and Design Features

Designed by Hansmeyer and Dillenburger, the theatre can accommodate 45 guests. Guests enjoy a panoramic view of the surrounding mountains while seated under a vaulted ceiling.

- Removable Translucent Membrane. The tower’s exterior is fitted with a protective, lightweight membrane that can be removed for maintenance and offers insulation during winter seasons.

- Audio-Visual Integration. State‑of‑the‑art sound and lighting systems are built into the balcony design, ensuring an immersive experience.

Construction Highlights

During February, printing commenced for the initial eight structural columns that will constitute the building’s lower floor. The full construction will require roughly 900 hours of 3D printing across all elements.

Key Milestones

- February: Commencement of first eight columns

- Completion: Predicted 900‑hour total printing duration

3D Printing Milestone for the Tower

The initial eight columns began production on 1 February, setting the stage for the tower’s construction. In total, completing the tower will demand roughly 900 hours of 3D printing.

Key Facts

- Column Printing Commencement: 1 February

- Total Printing Time: 900 hours

- Final Output: Fully 3D‑printed tower

Exploring New Frontiers with 3D‑Printed Architecture

Recent advancements in 3D printing have opened the door to architectural designs that move beyond conventional construction limits. One standout example is the Tor Alva, a striking structure that showcases the potential of additive manufacturing.

How the Tor Alva Redefines Structural Design

- Y-Shaped Columns: The building’s skeleton consists of unique Y‑shaped supports, facilitating enhanced stability and allowing for unprecedented geometric freedom.

- Fluid Forms: Unlike traditional masonry or steel frameworks, 3D printing enables the creation of seamless, organic shapes that were previously unfeasible.

- Material Efficiency: By printing only the necessary layers, the design reduces waste and optimizes resource use.

Implications for Future Construction

Projects like the Tor Alva demonstrate that 3D printing is not merely a fabrication tool but a catalyst for architectural innovation. As this technology matures, we can anticipate buildings that combine structural resilience with artistic expression, reshaping skylines worldwide.

New freedoms, new challenges

Revolutionizing Architecture with 3D Printing

Architectural Freedom Beyond the Ordinary

The Tor Alva showcases how 3D printing can transform architectural possibilities. Its branching columns and wave‑like surface break traditional construction limits, offering a canvas where curves and intricate patterns evolve naturally.

Challenges & Opportunities

- Structural integrity must adapt to unconventional geometries.

- Material behavior under complex loads becomes a critical focus.

- New design workflows integrate digital fabrication from concept to construction.

Insights from an Architectural Visionary

Hansmeyer emphasizes the shift from standardized, ninety‑degree frameworks to fluid, expressive forms:

- “For the last century, architecture has been anchored by flat surfaces and orthogonal angles.”

- “The 3D printing method removes constraints—robots print straight lines or ornate curves without additional cost.”

- “For us architects, this freedom is simply exhilarating.”

Future Outlook

As digital fabrication advances, architects will explore:

- Dynamic façades that respond to environmental stimuli.

- Customized structural elements that blend form and function.

- Collaborative design processes that empower both engineers and designers.

Reimagining Architectural Columns Through 3D Printing

In contemporary construction, each structural column can showcase a distinctive surface pattern and artistic ornament, underscoring the transformative potential of 3D‑printing technology.

Key Highlights of the 3D‑Printed Column Design

- Custom Texture – every column is rendered with a one‑of‑a‑kind finish, allowing architects to blend aesthetics with function.

- Detailed Ornamentation – intricate designs can be embedded directly during the printing process, eliminating post‑fabrication labor.

- Material Versatility – from high‑strength polymers to engineered composites, the technology supports a wide range of building materials.

- Rapid Prototyping – design iterations are accelerated, enabling quicker adaptations to evolving project requirements.

Illustrative Case Study

The collaboration between designer Hansmeyer and construction specialist Dillenburger showcases this approach in a modern façade, where each column uniquely contributes to the building’s identity while maintaining structural integrity.

Outcomes Observed

- Reduced labor costs due to integrated ornamentation.

- Enhanced architectural expression through customizable patterns.

- Improved sustainability by optimizing material use.

Future Directions

As 3D‑printing continues to evolve, we can anticipate even more dynamic surface patterns that adapt to lighting, temperature, and environmental conditions, pushing the boundaries of architectural design.

Illuminating the Tor Alva: A Modern Twist on Classic Craftsmanship

Overview

The first eight columns of Switzerland’s Tor Alva tower are undergoing a lighting evaluation. Each column boasts a distinctive surface pattern and decorative layer, creating a unique “fingerprint” for the structure.

Artisanal Inspiration Meets Contemporary Engineering

Hansmeyer points out that integrating advanced technology can revive an artisanal quality that has faded from modern builds.

“It feels like stepping back before industrialization and mass production, into a period dominated by skilled, handcrafted work,” he explains.

Design Evolution and Practical Constraints

The original design featured straight vertical columns. However, research revealed that Y-shaped columns could better handle wind forces and structural loads, leading to a redesign.

Key Takeaways

- Each column is uniquely patterned, offering recognition like a personal signature.

- Technology is used to reintroduce handmade aesthetics to contemporary architecture.

- Y-shaped columns enhance resilience against environmental stresses.

A more ecological way of building

Eco‑Friendly Benefits of 3D‑Printed Concrete

According to Hansmeyer, one of the key strengths of 3D printing concrete is its reduced environmental footprint.

Traditional Construction Challenges

- Concrete structures are typically cast using formwork—rigid frames that shape the poured concrete.

- These forms must be fabricated, positioned, and later dismantled, generating significant waste.

- Structures are often built from solid columns or blocks, a requirement that ensures structural integrity but adds to material usage.

How 3D Printing Mitigates Impact

- By eliminating the need for physical molds, the process saves both materials and energy.

- The additive nature of 3D printing means concrete is deposited only where needed, minimizing excess output.

- Overall, the technique supports greener building practices without compromising durability.

Revolutionizing Architecture: Tor Alva’s Second Level Unveiled

A vivid 3D projection captures the second tier of Tor Alva, showcasing a striking central spiral staircase. The sketch was produced by Hansmeyer and Dillenburger.

Advantages of 3D Printing in Construction

- No Need for Traditional Formwork – Molds that normally support concrete are rendered obsolete.

- Less Concrete Consumption – Robots print only the outer shell, cutting material usage.

- Easy Disassembly at End‑of‑Life – The structure can be dismantled without much effort, reducing waste.

Impact on the Building Industry

The prevalent pollution in construction largely stems from surplus materials like concrete and leftover formwork. Tor Alva’s design illustrates how 3D printing can streamline this process.

Reversible 3‑D‑Printed Tower in Mulegns Adopts Modular Design

Hansmeyer/Dillenburger unveil a 3‑D‑printed tower featuring interchangeable columns that can be disassembled for future reuse.

Modularity at Its Core

In a recent description of the structure, the architects highlighted the tower’s modular construction:

“The entire tower is built in a modular fashion, with components that are simply screwed together,” they explained.

By using standardized screws, the tower can be easily taken apart.

Future‑Proofing Through Reusability

- Components can be unscrewed for removal.

- The tower can be disassembled for relocation.

- Parts may be integrated into other projects within the future.

Timeline and Placement

The tower will stand in Mulegns from June 2024 until its scheduled dismantling in 2029.

After the initial five years, the structure will continue its journey elsewhere, preserving resources and extending its functional life.

Accessibility & Comments

Readers can navigate the site via accessibility shortcuts.

Feel free to share thoughts or comments in the section below.