Turn Plastic Into Power: A Global Movement Unites to Recycle and Clean Up the Planet

Precious Plastic’s 1400‑Tonnes Milestone: Will Open‑Source Tech Unlock Mass Plastic Recycling?

Annual Impact Highlights

The Precious Plastic consortium successfully recycled approximately 1,400 tonnes of plastic across its distributed fabrication hubs in a single calendar year. This achievement represents a significant leap toward widespread, community‑driven circularity.

Key Success Factors

- Modular, low‑cost hardware: 3‑D‑printed components compatible with most common printers.

- Open‑source software: Design files and operational protocols freely available on GitHub and community forums.

- Global volunteer network: Thousands of local makers, universities, and NGOs collaborate in real time.

Challenges That Remain

- Feed‑stock quality: Consistent sorting of mixed plastic grades is still required

- Energy consumption: Scaling up without increasing carbon footprint

- Financial sustainability: Transitioning from volunteer‑based to a commercially viable model

Could Open‑Source Innovation Turn the Tide?

Unlike proprietary recycling plants that demand high capital, the Precious Plastic framework offers a transparent, collaborative model that can be adapted to local conditions. By removing licensing barriers, communities can:

- Purchase or build cost‑effective shredders and extruders with downloadable design files.

- Implement localized quality control through shared best‑practice guidelines.

- Integrate solar or wind power to offset energy worries.

What’s Next?

Future plans include expanding the design repository to cover higher‑grade polymers, and creating a mobile app that streamlines yield tracking across global sites. If these innovations reach critical mass, the open‑source movement could redefine how we treat plastic waste—from a problem to a resource.

In Summary

The 1,400‑tonne recycling figure demonstrates that distributed, open‑source solutions are not just theoretical—they’re tangible. The next phase will test whether these grassroots tools can scale to meet the global plastic footprint, potentially ushering in a new era of community‑driven sustainability.

From a Student’s Vision to a Global Recycling Movement

In 2014, a young designer named Dave Hakkens embarked on an adventure that would change how communities think about plastic waste. While studying at the Eindhoven Design Academy, he boldly released a free design for a plastic recycling machine, aiming to bring the technology to everyday people.

The Core Idea

The machine was engineered with a single purpose in mind: to make plastic recycling accessible at scale. By focusing on parts that are

- easily replicable

- simple to repair

Hakkens lowered the learning curve, enabling neighbors to build and operate these machines without heavy technical expertise.

A Catalyst Moment

That same year, the design sparked an unexpected wave of enthusiasm. Three independent groups in different locations each managed to replicate the system, building their own version of the recycling apparatus. Their collective effort instantly birthed what is now widely known as the Precious Plastic project.

Why It Matters

Beyond the immediate technical achievement, Precious Plastic created a platform where local communities could collectively address plastic waste. With a low barrier to entry, these machines have become the cornerstone of countless community-driven recycling initiatives.

‘Teach a man to fish’

Open‑Source Resources for Plastic Recycling

All materials produced by the initiative—including machines, tutorials, tools, and design schematics—are distributed freely online under open‑source licenses. This approach allows anyone, anywhere, to launch their own plastic recycling endeavor.

- Machines available for global purchase and shipping.

- DIY-friendly designs that can be replicated, repaired, or refined using conventional parts.

- Step‑by‑step tutorials for assembling and operating the devices.

- Toolkits and product concepts ready to be adapted to local needs.

Getting Started

Whether you prefer a ready‑made machine or wish to build one yourself, the resources from the project provide everything you need to begin turning waste plastic into useful products.

Lowering the Bar for New Junk‑Recycling Innovators

In a decisive shift, the Precious Plastic project has rolled back the entry barrier, inviting fresh talent to dive into the recycling arena.

What the Movement Looks Like Now

- More than 2,000 plastic‑recycling hubs have registered—spanning 56 nations.

- Founders tweak the original four‑step machinery, tailoring it to local needs.

- Entrepreneurial ventures thrive, creating job opportunities and spreading plastic‑recycling awareness on the ground.

Why This Matters

“Our core aim was simple: generate far more plastic recycling,” Martin de Voos recalls. He began with the project in 2017, during a gap year between a bachelor’s and master’s in Industrial Design, contributing to the design of version three of the conversion machines.

The Process in a Nutshell

Ideas surface among community members, often sparked by what others have done or what could push the network forward. Funding is sought, successes are refined, and once polished, the results are broadcast online for worldwide replication.

Related Insights

From Seaweed’s endeavors to remove plastics from stadiums and snack boxes to the excitement of Precious Plastic’s new accessibility, the movement keeps momentum on its toes.

Plastic waste remains an intractable problem

When Plastic Becomes a Bird’s Diet

By 2050, almost all birds are estimated to have ingested plastic. This startling statistic highlights the escalating crisis of plastic waste, which now dominates the environmental agenda worldwide.

Current Recycling Challenges

- Only 8‑10% of plastic is ever recycled.

- The majority ends up in landfills, natural habitats, and the seas.

- Rising energy and labour costs make virgin plastic cheaper than high‑quality recycling.

- Many countries lack the necessary infrastructure to support large‑scale recycling operations.

Wildlife at Risk

Wildlife, especially fragile ecosystems, bears the brunt of this pollution wave. In 2025, Italian researchers discovered microplastics in the ovaries of several women—a finding that sparked alarms about potential effects on fertility rates.

Why the Recycling Industry Stalls

Despite the existence of recycling technologies, the expansion of the sector is sluggish. Investors hesitate to back a market that seems too volatile and costly to scale.

Enter Precious Plastic

Instead of waiting for established companies to turn plastic recycling into a profitable venture, Precious Plastic has taken a bold step. They have lowered the entry threshold for new players, inviting a wave of innovators to join the fight against plastic pollution.

What This Means for the Future

By democratizing the recycling process, Precious Plastic aims to build a resilient network that can adapt to local needs, reduce waste, and, most importantly, protect both biodiversity and human health from the pervasive threat of plastic.

Turning Waste into Community Strength: The Global Rise of Local Recycling Initiatives

From the bustling streets of Singapore to war‑torn Ukraine, entrepreneurs are proving that humble plastic can be transformed into a source of pride, innovation, and livelihood.

Precious Plastic: Making Recycling Accessible

“Precious Plastic was one of the first projects where small, personal solutions to larger challenges can be realized, giving people the confidence that they can contribute to the solution,” says founder de Voos. By offering best‑practice business tools, the initiative has helped entrepreneurs worldwide turn plastic recycling into sustainable enterprises.

Scaling Impact Through Local Startups

- Plastify (Singapore) – Launches a PET‑bottle collection scheme and partners with hospitals to repurpose medical packaging into products. This includes exclusive merchandise for the Formula 1 Grand Prix.

- Plastiz (Turin, Italy) – Converts abandoned traffic lights, coffee pods, and more into architectural and interior design sheets.

- No Waste Ukraine – Amidst conflict, works to transform waste sorting into a cultural norm. Founder Eugenia Aratovska highlights a shift from Soviet‑era shame to a new sense of pride and identity.

No Waste Ukraine: From Workshop to Cultural Shift

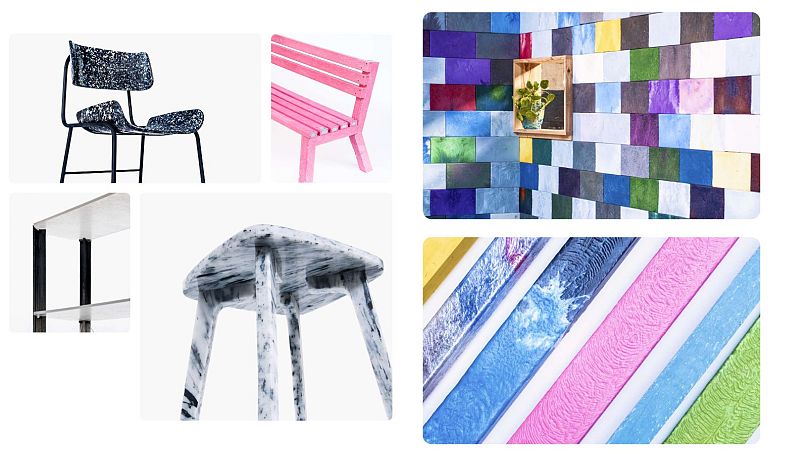

After opening a Precious Plastic workshop, No Waste Ukraine has produced café furniture, notebook covers, and branded gifts—all crafted from recycled plastic. This not only reduces waste but also showcases the creative possibilities when communities embrace recycling.

Looking Ahead

Across Europe, the challenge of collecting items like nappies, smartphone glass, and cigarette butts is growing. By replicating the success stories of Precious Plastic and its local partners, there is hope for scalable solutions that keep communities economically and environmentally viable.

Plastic recycling requires long-term, multi-stakeholder commitment

Precious Plastic: From Volunteer Power to Sustainable Future

Community‑Driven Success

Precious Plastic thrives thanks to the dedication of volunteers who contribute their time, skills, and resources. The project began with a small but committed group of twelve individuals who worked almost daily without compensation. That grassroots energy has propelled the movement forward, allowing the community to design, build, and operate plastic‑recycling machines worldwide.

The Fragility of an Altruistic Foundation

However, the same reliance on voluntary efforts also renders the initiative vulnerable. As the organization grows, operational costs—especially rent—become unavoidable. When a new version of the equipment is launched, enthusiasm wanes, and financial strain can stall progress. Presently, version five is on hold due to budgetary limitations.

Technology That Lives On

Despite these challenges, de Voos remains optimistic. He points out that the machines themselves are still functional and valuable. Anyone interested can step in and adopt the technology; the platform remains open for future developers.

Beyond Plastic Recycling

While Precious Plastic has made significant strides in reducing plastic waste, de Voos calls for a broader appreciation of those working in the recycling sector. He stresses the need for governmental backing—policy, subsidies, and shared responsibility—to support local initiatives. Such cooperation would accelerate the transition from raw material to finished product, closing the loop on waste.

Related Initiatives

- Coffee Cup Returns in Denmark: A city pays citizens to return coffee cups, aiming to boost recycling rates.

- Repair Café: Locals volunteer to fix broken items, promoting a culture of repair over replacement.

The journey toward a circular economy is complex, but with continued volunteer engagement and institutional support, projects like Precious Plastic can keep driving sustainable change.

Recycling is only as good as the plastic produced

Achieving a Truly Circular Plastic Future

Reaching real circularity in plastics demands a fundamental overhaul, stretching from the very first step of production right through to the final disposal stage.

Current Production vs. Recycling Capabilities

- About 460 million metric tonnes of plastic are manufactured annually, according to the United Nations Environment Programme.

- Most of this material is engineered so that 1:1 recycling isn’t feasible—often it is impossible to reprocess the same polymer into new products.

- Even with innovative, hyper‑local initiatives and open‑source tools, the sheer volume of virgin plastic production far outpaces what conventional recycling can handle.

Emerging Alternatives to Traditional Plastics

- Notpla offers eco‑friendly edible packaging in the UK, turning totem‑free options that break down quickly.

- A Japanese breakthrough creates a polymer that safely dissolves in seawater, mitigating marine pollution risk.

- These solutions highlight that a worldwide reliance on virgin plastics isn’t inevitable and that disruptive, greener materials are already surfacing.

Global Momentum: The Plastic Treaty to Watch

October’s August negotiations aim to forge a global plastic treaty—the first step toward persuading manufacturers to adopt more circular designs and production methods. Whether industry leaders will rally behind it remains to be seen:

- If major players commit, large‑scale recycling could become a reality.

- Even if they falter, grassroots movements—such as Precious Plastic—continue providing tangible, community‑driven pathways toward waste reduction.

Updated Attribution Note

The previous text incorrectly credited a statement to No Waste Ukraine project leader Khrystyna Baranovska; it has now been corrected to attribute the quote to founder Eugenia Aratovska.